Legacy Pipeline Inspections Weren’t Designed for Scale — Until Now For decades, pipeline...

Powerlines: Turns, Terrain, & Truth - Only Helicopter Drones Belong Here

Why Powerline Inspections Demand Precision: The Case for the Xplorate's SDO50V3

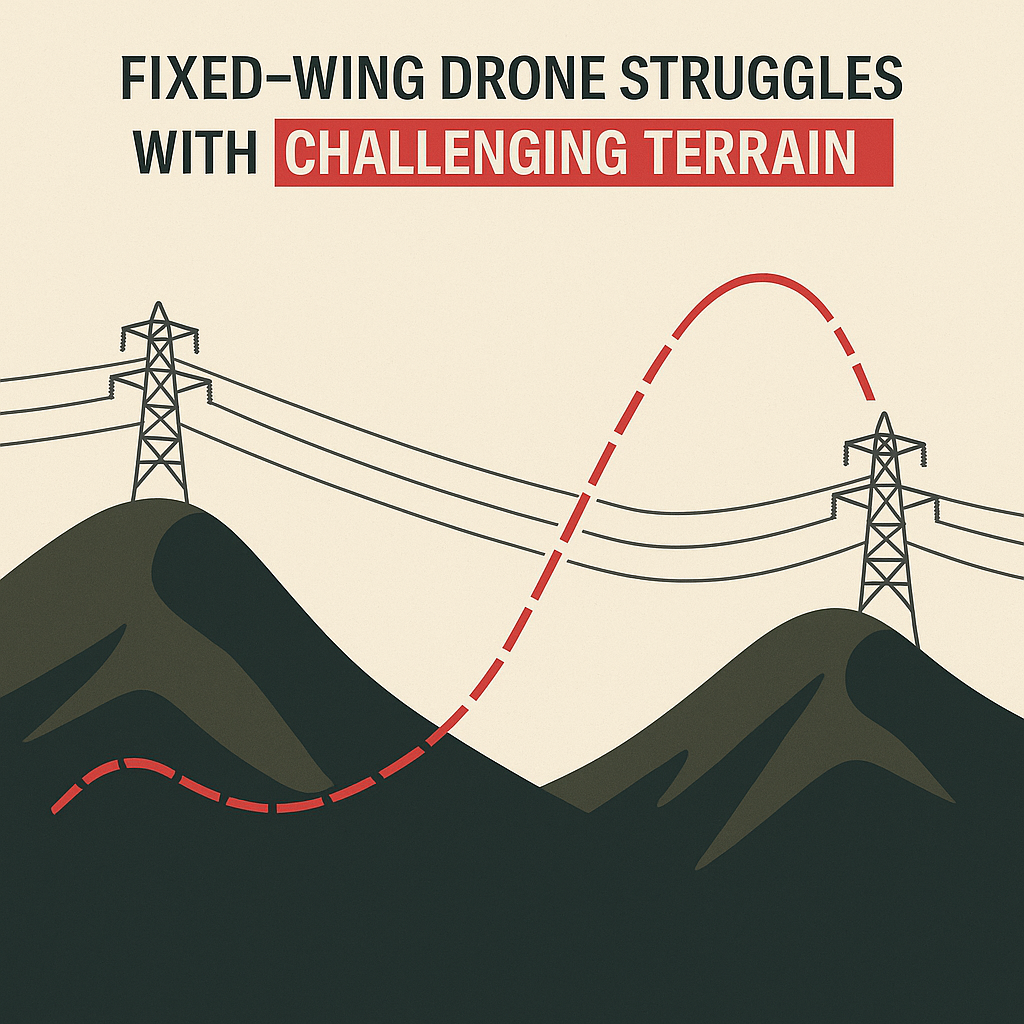

Powerline inspections are vital for maintaining reliable energy infrastructure, yet they present unique challenges due to the complex, winding paths of powerline networks.

These essential arteries of the grid traverse rugged terrain, dense vegetation, and tightly constrained corridors, requiring a level of precision that high-speed drones often fail to deliver.

Xplorate's SwissDrones SDO50V3, a rotary-wing RPAS, redefines inspection efficiency with its ability to navigate intricate routes, capture comprehensive data in a single pass, and ensure safety in challenging environments.

This post explores why precision, not speed, is the key to effective powerline inspections and how the SDO50V3 sets a new standard.

The Challenge of Powerline Geometry

Powerlines don’t follow predictable paths. They twist, climb, and dip to navigate terrain, property boundaries, and infrastructure constraints. Two anonymised datasets from real inspection routes highlight this complexity:

Dataset A: Rolling Terrain with Sharp Transitions

-

Characteristics: Stair-step directional changes, up to three angular deflections within 1.5 km, and shifting land use (forest edges, paddocks, hilly corridors).

-

Challenge: Fixed-wing or eVTOL drones, travelling at 65 km/h, lack the agility to yaw or bank tightly, often overshooting turns and misaligning sensors.

-

SDO50V3 Advantage: Its rotary-wing design enables smooth flat turns and precise tracking, maintaining optimal sensor alignment along the entire route.

Dataset B: Hilly Topography with Dense Turns

-

Characteristics: Seven directional changes in 4 km, rapid elevation shifts over escarpments, and narrow corridors with asymmetric vegetation.

-

Challenge: High-speed drones require multiple passes to capture data, disrupting continuity and increasing flight time. Additionally, maintaining a constant height above the asset for LiDAR data collection is nearly impossible due to their reliance on forward momentum and limited vertical agility.

-

SDO50V3 Advantage: The SDO50V3 hovers and loiters as needed, following the line’s elevation and maintaining a consistent height above the asset for precise LiDAR data capture, completing inspections in a single pass.

Data Quality: The Cost of Speed

High-speed drones sacrifice data quality for efficiency, leading to significant losses. Across a 150 km powerline network, we estimate:

|

Loss Factor |

Estimated Data Loss |

|---|---|

|

Turns & Directional Realignment |

26% |

|

Sensor Tilt & Off-Angle Framing |

8% |

|

Multi-Pass Inefficiencies |

5% |

|

Total Estimated Data Loss |

40% |

This translates to 60 km of compromised or missing data—unusable for AI analytics or failing quality assurance standards. The challenge of maintaining a constant height for LiDAR exacerbates this, as fixed-wing and eVTOL drones struggle to adjust to rapid elevation changes, resulting in inconsistent data.

The SDO50V3, with its stable flight, precise height control, and sensor alignment, reduces data loss to near zero, ensuring high-fidelity outputs in a single pass.

Airspace and Safety: Minimising Risk

Airspace and Safety: Minimising Risk

Powerline inspections are as much about airspace safety as data collection. High-speed drones require wide buffers (50–200 metres) to accommodate their turning radii and stable flight paths, increasing their airspace footprint.

This complicates operations near roads, private property, or sensitive zones, often requiring multiple passes for conductors, towers, or thermal imaging. Each pass adds takeoff/landing events, mission complexity, and cumulative risk.

The SDO50V3 minimises these concerns:

-

Compact Flight Path: Flies low and tight to the asset, requiring minimal lateral or vertical buffers.

-

Single-Pass Efficiency: Captures all data in one continuous flight, reducing total flight time by up to 30% compared to multi-pass operations.

-

Hover Capability: Pauses or holds position for reinspection or navigation checks, ensuring precise height control for LiDAR and enhancing safety in complex environments.

Sensor Payloads: Comprehensive Data in One Flight

Effective inspections rely on robust sensor payloads:

-

LiDAR and Photogrammetry: Essential for structure modelling, clearance measurement, and textured 3D reconstruction. LiDAR requires a constant height above the asset for accurate data, which fixed-wing and eVTOL drones struggle to maintain due to their fixed flight paths and limited vertical control. Both sensors must be captured simultaneously for accurate data registration.

-

Infrared (IR) and Corona (UV): Valuable for detecting overheating components and electrical arcing, but secondary unless specific faults are targeted.

High-speed drones struggle to carry multiple sensors without compromising manoeuvrability or increasing vibration, which degrades data quality. Larger airframes required for heavier payloads reduce efficiency in tight corridors.

The SDO50V3 excels here:

-

Integrated Payload: Supports LiDAR, photogrammetry, IR, and corona sensors in a single, vibration-dampened payload bay.

-

Advanced Stabilisation: Ensures precise sensor alignment and consistent height above the asset through turns and elevation changes, delivering reliable LiDAR and photogrammetry data.

-

High Capacity: Handles up to 45kg of payload, enabling comprehensive data capture without sacrificing agility.

Addressing Concerns: Is Rotary-Wing More Complex?

Some assume rotary-wing drones like the SDO50V3 require more complex training than fixed-wing platforms. However, the SDO50V3’s integration with Xplorate’s automation platform simplifies operations significantly.

Xplorate automates a vast majority of flight and inspection actions, with continuous improvements reducing the learning curve for operators. This ensures ease of use comparable to simpler drones, while delivering:

-

Reduced Flight Complexity: Single-pass missions eliminate the need for multi-flight planning and data stitching.

-

Higher ROI: Improved data quality and reduced operational time lower costs, showing savings in inspection programmes using rotary-wing UAVs.

Comparison: SDO50V3 vs. Fixed-Wing/eVTOL

|

Feature |

SDO50V3 |

Fixed-Wing/eVTOL |

|---|---|---|

|

Flight Behaviour |

Hover-capable, speed as required, precise |

Fast, requires forward momentum |

|

Corner Handling |

Effortless turns and holds |

Overshoots, requires rerouting |

|

Image Stability |

Low vibration, perfect framing |

Blurred or tilted views |

|

Passes Required |

Single-pass coverage |

Often 2+ passes for full capture |

|

Corridor Compliance |

Operates in narrow, obstructed terrain |

Needs large buffers and clear airspace |

|

Elevation Following |

Tracks terrain precisely, maintains constant LiDAR height |

May require disengagement, inconsistent LiDAR height |

|

Airspace Risk |

Minimal, compact flight path |

Higher, broader buffers required |

|

Sensor Integration |

Multi-sensor, real-time sync |

Vibration and weight challenges |

|

Scalability |

Repeatable, fleet-deployable |

Complex routing and stitching issues |

The SDO50V3’s capabilities are amplified by its seamless integration with Xplorate’s Data Intelligence division, creating a comprehensive solution for powerline inspections.

Beyond capturing high-fidelity data, Xplorate’s advanced analytics platform processes and interprets the SDO50V3’s LiDAR, photogrammetry and more, delivering actionable insights for maintenance and risk management.

This end-to-end approach—from precise data collection to automated analysis—eliminates the need for multiple vendors, streamlines workflows, and ensures consistent, high-quality results. With Xplorate, utility operators gain a single, scalable platform that transforms raw data into informed decisions, enhancing efficiency and reliability.

Conclusion: Built for Speed? That’s the Problem.

Fixed-wing and eVTOL drones are built for speed.

But powerline inspections aren’t about speed — they’re about precision, alignment, and real-world adaptability. Speed skips details. Speed overshoots. Speed compromises the very data that asset owners rely on.

At Xplorate, we take a different approach. We deploy the SwissDrones SDO50V3 because it’s engineered for the job — not just for the airspace. It flies with deliberate control, hugging terrain and following the actual geometry of the powerline network, not a simplified approximation of it.

While fast-moving aircraft require broad buffers, multiple passes, and post-collection correction, the SDO50 captures everything — LiDAR, photogrammetry, thermal, and UV — in one stable, low-risk flight.

And we don’t stop at data capture. Our intelligence pipeline transforms that raw flight data into clear, actionable insights — identifying faults, measuring vegetation encroachment, and modeling asset condition across every span and tower.

We don’t rush. We don’t guess.

We deliver inspection-grade data that’s right the first time.

In a sector where safety, compliance, and uptime matter, Xplorate’s model isn’t just different —

it’s the one that works.

Slow where it matters. Sharp where it counts. That’s the Xplorate standard.

Let the Grid Guide the Flight